An air brake chamber is measured by locating size markings on the brake chamber or by measuring the diameter of the clamp holding the chamber together. Measuring the diameter requires a special tool, whereas locating the size markings may require the removal of dirt, corrosion or paint. Brake chamber sizes can be found in the vehicle owner's manual.

Common sizes of brake chambers include 16, 20, 24, 30 and 36. The size refers to the square inches of effective area in the chamber, therefore a size 30 brake chamber means there are 30 square inches inside. A size 3030 brake chamber has an outside diameter of 8 3/32 inches, according to Fire Apparatus & Emergency Equipment Magazine. The size of a brake chamber is important because it determines the brake adjustment limit.

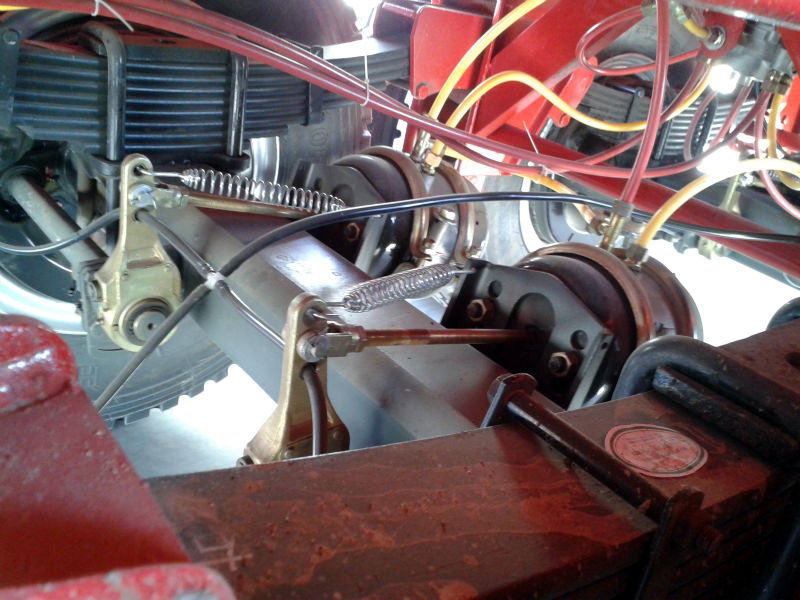

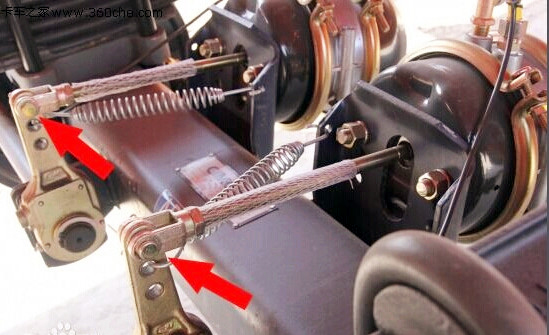

Air brake chambers 3030 fill with air upon pushing the brake pedal, thereby activating pushrods that apply the brakes to the wheels. Adjustments need to be made with pushrods so that they do not exceed limits. If pushrods are over-adjusted, they can become damaged. These rods have indicators to ensure proper inspection of the air brakes. These devices should be inspected daily for wear, especially with companies that use air brakes on a regular basis.

Replacing a Spring Air Brake Chamber

Replacing a Spring Air Brake Chamber

cage it off, mark your hoses, colored zip ties or a bit of telephone wire works good, disconnect your hoses, now disconnect your clevis, and you're ready to unbolt from the axle. Take that all to your bench take the clevis off the new brake can and leave the nut, cage it, take the clevis off your old brake can and set up next to your new one and determine where you need to cut the push rod. cut the push rod and run your lock/jam nut off the allthread because you left it on there so you don't have to go chasing threads, put your lock nut and clevis back on and repeat what I said at the beginning only backwards. get everything all back together and now adjust your brakes, all of them while you're under there.

Now I'm sure that someone else on here will come along and give a better detailed step by step instructions on this, but if what I just rambled on doesn't make sense, then I'd be a bit hesitant about replacing your own brake cans, as much as the DOT likes to go after a guy (driver, mechanic, company) for brake infractions, the liability may be less to just have it done. Let alone safety liability for one's one personal well-being...

Also, if the old can is rusted, I would VERY HIGHLY recommend AGAINST using any air, or impact tools to cage that brake can off, and position your body similar as to if you were doing show trimming on a calf that likes to kick, as little of your body in the 'line of fire' as possible. You should make sure however you get rid of that old brake can is going to disarm it before sending it to scrap.

Go to about the 13 minute mark of this video, it's a brake can off of a loader, and a cheesy old safety film, but it gives you a idea of what that spring will do.

没有评论:

发表评论